Today’s demand for flexible and economic production of steel structures plays a vital role in Building, Construction and Infrastructure sectors. The average share of the construction sector in global steel consumption at around 50-55% implies that irrespective of the stage of growth of the economy, revival of steel demand critically hinges on development and expansion of this sector. Some advantages of steel include strength, energy efficiency, design flexibility, fire resistance, ease and speed of assembly, material cost advantage, less deterioration over time, less maintenance, high quality homes, better resale value, a cleaner work site with less wastage and eco-friendliness.

Jindal Steel and Power Limited (JSPL) pioneered the production of Hot Rolled Parallel Flange Beams, Columns and Sheet Piles in India, which are extensively used in Building, Construction and Infrastructure. A Parallel Flange Beam/Column provides substantial design optimization compared to tapered beams, due the multiple sectional weights available with the same nominal depth, as against the single sectional weight of a tapered ISMB. JSPL offers customers a wide range of products as per National and International standards, which are available in different unit weights with superior strength, higher axial and bending load bearing capacities.

JSPL has been in the forefront of Swadeshi Movement in Steel – be it using DRI (both Coal and Syngas based) in lieu of the imported low-ash Coking Coal dependent BF Route or in being the first producer of Parallel Flange Beams in India, as a substitution for imports. Keeping the clarion call of Honourable Prime of India, of Make in India and the road-map of higher usage of steel in Construction, as laid out in NSP of 2017, JSPL began promoting High Strength Steel in lieu of E250 Grade Steel that was generally available. As a thumb rule, every 1% increase in YS (Yield Strength), results in 0.5% saving in steel consumption.

Thereby when a consumer moves from YS 250 MPa (E-250 Grades) to YS 350 MPa (E-350 Grades), the increase in YS is 40% (100 Mpa over 250 MPa) and thereby savings in Steel is 20%. A primary concern in moving from RCC to Steel, was the higher initial cost of Steel. This difference is cost comes down substantially with use of High Strength Steel. Further savings are achieved in terms of transportation, larger span widths, leaner sections etc. It is fulfilling to note that E350 Grade is gradually becoming the standard grade in most project designs and most airports, refineries, industrial sheds and pre-engineered buildings.

Development Of Steel For Building And Construction And Infrastructure Sectors

The rolled steel products for usage in building, construction and infrastructure are currently standardised in the IS 2062 which defines different yield strength levels like E250-E650. While in India we still design with E250 Grade, in most advanced economies E350BR/S355JR is the default standard for design. In order to achieve higher strengths, it is necessary to design the chemistry by adding micro alloying elements to the standard chemistry of E250BR, for getting the high tensile properties. The purpose of adding micro alloying elements like Niobium (Nb), Chromium (Cr) and Vanadium (V) to the standard chemistry is to get the high strength properties with the challenge remaining that the cost towards these additions is substantially lower than the savings in steel achieved by using such High Strength Steel.

The rolled steel products for usage in building, construction and infrastructure are currently standardised in the IS 2062 which defines different yield strength levels like E250-E650. While in India we still design with E250 Grade, in most advanced economies E350BR/S355JR is the default standard for design. In order to achieve higher strengths, it is necessary to design the chemistry by adding micro alloying elements to the standard chemistry of E250BR, for getting the high tensile properties. The purpose of adding micro alloying elements like Niobium (Nb), Chromium (Cr) and Vanadium (V) to the standard chemistry is to get the high strength properties with the challenge remaining that the cost towards these additions is substantially lower than the savings in steel achieved by using such High Strength Steel.

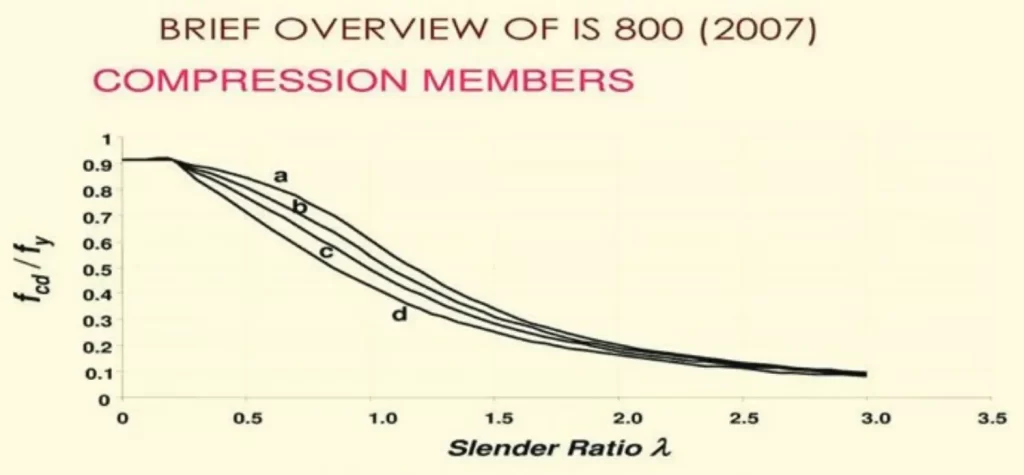

Rolled Parallel Flange Beams and Columns have distinct advantages over built up sections and hollow sections, as enumerated in the buckling curve below

a = Parallel Flange Beams, b = Built up Sections, c = hollow sections, d = cold formed section

With SAIL joining in with its range of Parallel Flange Beam and regular availability of E350 Grades from both SAIL and JSPL, all major structural steel consumption sectors like Refineries, Metros and Airports have moved to E-350 as the default grade for design and steel usage optimization.

This paper focuses on the usage of E410 and E450 Grade Steel in various Building, Construction and Infrastructure Projects resulting in significant design optimization and savings in total steel consumption. We herein highlight the development of various steel grades and product, wherein by designing appropriate chemistry with micro alloy additions and rolling at low Finishing Temperature, improved mechanical properties like high yield and tensile strength along with specified elongation was achieved. JSPL developed these innovative new products for High Strength Steel in response to market requirements for stronger and lighter steels. It involved working closely with designer and architects to convince usage of this high-strength steel and allaying the fears involved in no alternatives available in case JSPL failed to supply the designed sizes in the desired grades of E410/ E450/E550.

The usage of JSPL steel in various sectors as laid out in the National Steel Policy of 2017 is detailed below. We have highlighted only those projects wherein E-410/E-450 Grade Structure Steel from JSPL have been used.

Structures And Flyovers

- E-410 Structure Steel by ITD Cementation for Kolkata Metro

- E-410 Structure Steel by CEC-ITD CEM-TPL JV for Mumbai Metro

- E-410 Structure Steel by Dogus-Soma JV for Mumbai Metro

- E-410 Structure Steel by Transtonnelstroy-Afcons JV for Kolkata Metro

Prefabricated Structures In JSPL Fabrication Shops In Punjipatra And Angul

- E-450 Structure Steel for Mist Avenue Project in Noida

- E-450 Structure Steel for Alphathum by Bhutani Group

Commercial And Residential Buildings

- E-450 Structure Steel for Commercial Buildings of

- Phoenix Group in Hyderabad

- E-450 Structure Steel for Dhirubhai Ambani Convention

- Centre at BKC, Mumbai

- E-410 Structure Steel by Success Steel Structures for High

- Rise Building in Africa.

- Recently finalised order for E-450 Structure Steel for

- the prestigious Central Vista Project in New Delhi

- (supplies to commence in July 2020)

Rail/Road Bridges And General Fabrication

- E-410 Gr C Structures with Impact Values of min 27 Joules

- @ -200

- C for MG Setu Project in Patna by Afcons Sibmost JV.

- E-410 Grade Parallel Flange Beams for Weigh Bridges

- by Essae Digitronics.

- E-410 Grade Beams by Trailer Chassis Manufacturers

Sheet Piles In Infrastructural Development

- E-410 Grade Sheet Piles for the Pragati Maidan Underpass

- by L&T ECC

- E-410 Grade Sheet Piles in Railway Projects across the

- Country.

JSPL Products In Various Prestigious Projects Of India

SPL has supplied its signature steel products such as parallel flange beams, columns and Sheet Piles to various prestigious projects like:

– Telangana Police Head Quarters – Hyderabad

Kaleshwaram Irrigation Project – Telangana

IKEA -Hyderabad and Mumbai

Kia Motors – Anantapur

Statue of Unity – Gujarat

ITPO -Pragati Maidan

Airports of Delhi, Bengaluru, Hyderabad and Vijayawada

Alphathum

Bhutani

High Rise buildings and Sheet Piles to L&T for embankment projects. Photos of such projects are as below and involve E-350/E-410 and E-450 Grade Steel Structures.

Alphathum Tower, Noida

Alphathum Tower, Noida

H20 IT Park- Greater Noida

Windsor IT Building, Noida

NICL Corporate Tower, Kolkata

M3M-IFC, Gurugram

K. Raheja Corp, Hyderabad

K. Raheja Corp, Hyderabad

Embassy Tech Village, Bangalore

Conclusion

JSPL has been striving for excellence in development of High Strength Steel that fulfils the customer requirements and creates value for the Designers, Architects and end-users. To give a greater fillip to the use of Steel in Construction and the overall life cycle cost advantages of Steel over concrete, it is necessary that increased design happens in E-350 Grade Steel and other High Strength Steel. To enable the same, it is essential that all Government projects, Railway OHE Masts, Railway Bridges and other Infrastructure Construction move to E-350 Grade as the minimum base grade, in all applications. This shall help in greater appreciation of the life cycle cost and the objective of the National Steel Policy of 2017 towards increasing per-capita steel consumption shall be met expeditiously.

Leave a Reply

You must be logged in to post a comment.