What are hollow sections?

Known for their strength, versatility, and sleek appearance, hollow sections provide robust support while being lightweight. Their high strength-to-weight ratio makes them ideal for various applications, from building frameworks to architectural elements. Hollow sections not only offer excellent durability and structural integrity but also bring an aesthetic appeal to modern designs, making them a preferred choice for both practical and decorative uses in the construction industry. This includes both square hollow sections and rectangular hollow sections, which are widely used for their structural benefits.

Key features and benefits

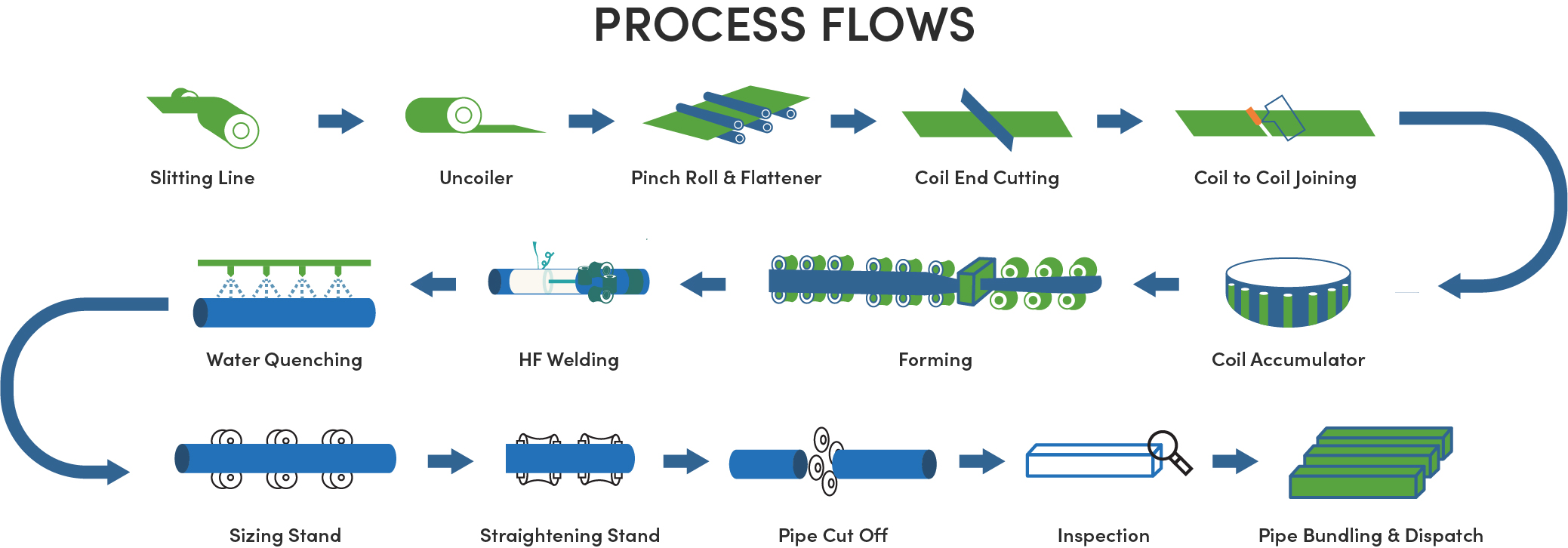

Technology

Direct Forming Technology (DFT) revolutionises the production of hollow sections, offering unparalleled flexibility, enhanced production capabilities, and reduced costs. This innovative approach allows for the creation of any size without roll changes, significantly cutting down setup times. Both square hollow sections and rectangular hollow sections benefit from this advanced manufacturing process.

Advantages of Direct Forming Technology (DFT)

- Precise Dimensional Tolerance: Delivers exact dimensions with controlled corner radii.

- Consistent Dimensions: Ensures uniformity across the entire length and batch.

- High-Quality Surface Finish: Provides a smooth and superior finish.

- Customisation and Flexibility: Offers greater adaptability to meet specific needs, particularly for customised square hollow sections and rectangular hollow sections.

- Reduced Lead Times: Speeds up production for faster delivery.

Advantages of Sheet Piles

Tailor Made Solution

Prefabricated Product With High Quality Control

Faster Execution Time

Longer Design Life

Longer Design Life

Flexible Delivery Support

Technical & Commercial Support

Preliminary Advice

Driving Recommenda Tions

Technical Assistance On And Off Site

Product Range – Square hollow sections

| Dimensions | Thickness | |

|---|---|---|

| 150mm X 150m | 4mm to 22mm | 600mm X 600mm |

Rectangular hollow section (RHS)

| Product Range | Thickness | Length |

|---|---|---|

| Mill 1 - Min 100mm X 200mm Max 150mm X 450mm | 4mm to 22mm | 4 to 14 M (Can supply up to 24M length) |

| Mill 2 - Min 300mm X 350mm Max 400mm X 600mm |

Applications

Shopping Malls

Stadiums

Railway Station/ Bus Stands

Industrial Sheds

Airport Terminal

Truck and Bus Body Manufacturing

Material Racks

Power Plants

Other Infrastructural Projects

Related Products

Frequently asked questions (FAQs)

What are hollow sections used for?

Hollow sections are used in various construction and engineering projects due to their strength, lightweight properties, and aesthetic appeal. They are commonly used for building frameworks, columns, beams, trusses, and architectural elements. Their versatility also makes them suitable for applications in bridges, industrial structures, and even handrails and fencing.

What are the benefits of using hollow sections over solid steel sections?

Hollow sections offer several advantages over solid steel sections, including a superior strength-to-weight ratio, which reduces the overall weight of structures without compromising strength. They provide better resistance to bending and twisting and are more efficient in terms of material

usage. Additionally, hollow sections, such as square hollow sections and rectangular hollow sections, can be easily customised, cut, and welded to fit various design needs

How are hollow sections manufactured using Direct Forming Technology (DFT)?

Direct Forming Technology (DFT) streamlines the production of hollow sections by allowing for the creation of any size within the mill’s range without roll changes. This innovation reduces setup times and offers precise dimensional control, consistent quality, and a superior surface finish. DFT enables higher customisation and flexibility, ensuring products meet specific project requirements quickly and efficiently.

Are hollow sections environmentally friendly

Yes, hollow sections are considered environmentally friendly. Their production uses fewer resources compared to other materials, and they are both reusable and recyclable. This sustainability aspect makes hollow sections a responsible choice for modern construction, reducing waste and promoting the reuse of materials