In the world of construction, the stability and durability of a building lie in its foundation and framework. This crucial aspect is where structurals come into play. Structurals, also known as structural steel shapes, form the backbone of modern construction, providing essential support, strength, and versatility to buildings and infrastructure. Let’s understand what structurals are, the various types available, and why they are considered the best choice for construction projects.

What are Structurals?

Structurals are a category of steel shapes designed to withstand various types of loads, including dead loads (the weight of the structure itself), live loads (occupant and furniture weight), wind loads, seismic loads, and more. These steel sections have specific cross-sectional shapes that optimize their strength-to-weight ratio, making them ideal for supporting heavy loads over long spans without excessive deflection or deformation.

Types of Structurals

I-Beams (or Universal Beams – UB and Universal Columns – UC):

I-beams, named for their distinctive “I” shape, are one of the most used structurals. They consist of a horizontal top flange and a vertical web, with another horizontal bottom flange. This design distributes loads evenly and efficiently along the length of the beam. I-beams are suitable for a wide range of applications, from supporting floors and roofs to creating stable frames for buildings and bridges.

H-Beams (or Wide Flange Beams – WF):

H-beams, also known as wide flange beams, have a wider profile compared to I-beams, resembling the letter “H.” This design offers enhanced load-bearing capabilities and resistance to torsional forces. H-beams are commonly used in high-rise buildings, as well as in the construction of bridges and industrial structures.

Channels (or C-Shaped Sections):

Channels have a “C” shape and are widely used in construction for their versatility and ease of installation. They are commonly utilized as secondary supports, purlins, and bracing elements. Channels are also prevalent in various industries due to their ability to resist bending and torsional stresses.

Angles (or L-Shaped Sections):

Angles, as their name suggests, have an “L” shape with two legs of equal or different lengths. They are often employed as braces, lintels, or corner supports in structures. Angles provide strength and stability to buildings and can also be used for aesthetic purposes.

T-Sections (Tee Beams – T):

T-sections resemble the letter “T” and are commonly used in the construction of bridges, as well as for creating columns and beams with greater load-carrying capacity.

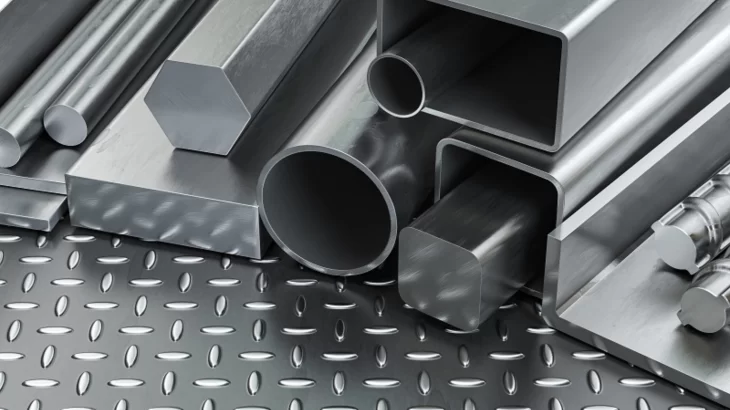

Hollow Structural Sections (HSS):

Hollow Structural Sections are manufactured in various shapes, such as square, rectangular, and circular tubes. These sections are lightweight yet robust, making them suitable for applications where weight reduction is essential, such as in automotive and aerospace industries.

Why are Structurals Best for Construction?

Strength and Durability:

Structural steel possesses an unparalleled strength-to-weight ratio, making it an excellent choice for carrying heavy loads while keeping the overall structure lightweight. Its durability ensures that buildings and infrastructure can withstand the test of time, reducing maintenance and repair costs.

Design Flexibility:

Structurals offer immense design flexibility due to the availability of different shapes and sizes. This adaptability allows architects and engineers to create innovative and efficient designs that meet specific project requirements.

Speed of Construction:

One of the significant advantages of using structurals is the ease and speed of construction. Prefabricated steel components can be manufactured off-site and then assembled quickly at the construction site, reducing project timelines and labor costs.

Sustainability and Recyclability:

Structural steel is highly sustainable, as it can be recycled and reused without compromising its quality. This feature aligns with the growing trend of environmentally conscious construction practices, reducing the overall environmental impact.

Resistance to Fire and Extreme Conditions:

Steel is inherently fire-resistant, providing an additional layer of safety to occupants in case of fire incidents. Moreover, structurals are designed to withstand extreme weather conditions, including earthquakes and hurricanes, ensuring the longevity and safety of the structure.

Cost-Effectiveness:

While the initial cost of structural steel may be higher than some other construction materials, its long-term benefits, such as lower maintenance and repair costs, energy efficiency, and faster construction times, make it a cost-effective choice in the long run.

Jindal Steel and Power (JSP) development revolves around customization, and our commitment to global technology leadership assures us that we are providing the greatest steel products possible to our devoted clients. JSP is honored to have started India’s industry for medium and heavy structurals. These steel sections provide superior strength, efficiency, and stronger axial and bending load-bearing capacities. Structurals are the natural choice for constructing robust, sustainable, and resilient buildings and infrastructure that will stand tall for generations to come.